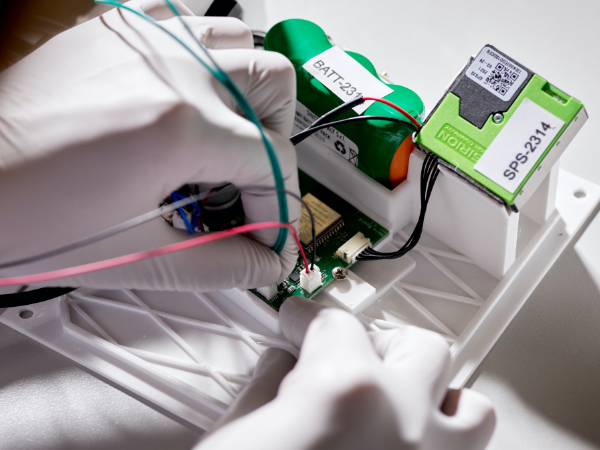

Clean Room assembly: safe, effective, controlled

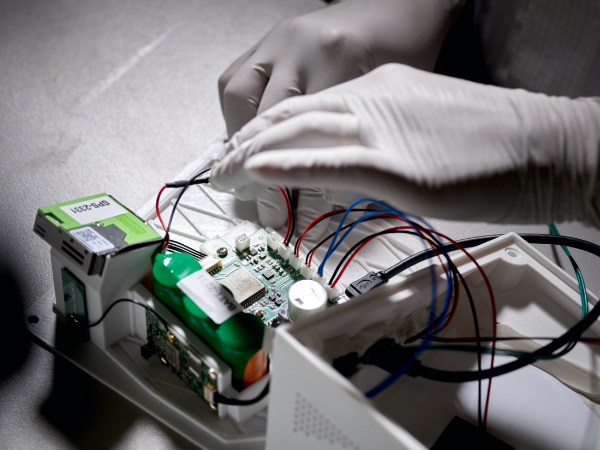

Panni & Lazzarini, always focused on customers requirements and proposal of efficient solutions to meet even the most demanding and complex markets, has an innovative clean room (or clean laboratory) to provide the service of assembly in Clean Room with high added value.

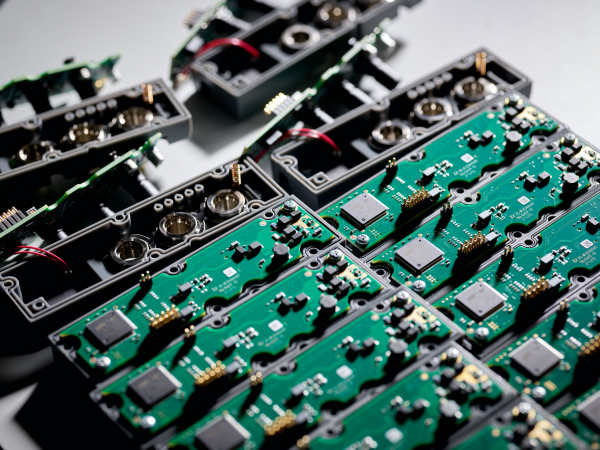

The assembly, testing and verification of components within a protected and controlled environment such as that of a modern Clean Room, are increasingly required in the production of medical products or in the assembly of elements for the food & beverage sector, as well as in the market of microelectronics or precision mechanics.

ISO 8 certified clean room and

workstations equipped with innovative instruments

Our clean-room has earned the ISO 8 certification and it is equipped with state-of-the-art equipment that allows total control of the production process, such as the ultrasonic washing machine, for thorough cleaning of components, and touch screens for real-time monitoring of assembly procedures and the progress of the work.

All our clean room assembly activities take place in full compliance with the procedures and standards agreed with the customer, to guarantee an excellent result that increases yield over time and the overall quality of production, offering a real competitive advantage to our clients.

Gray room assembly with ESD workstations

In addition to the clean-room, Panni e Lazzarini also has a gray room with ESD workstations. Our gray room is a structure of about 50 square meters used for the assembly of sensitive components and for the internal activities of product industrialization and research and development.Equipped with temperature and humidity control, the gray room allows precise and controlled assembly activities, also thanks to the ESD work areas, where the electrostatic current is correctly discharged to the ground to avoid interference in the processing of electronic groups and sub-groups.

Features of clean room assembly

Panni & Lazzarini's Clean Room assembly stands out for the following features:

- the presence of pure air with a reduced content of suspended powder microparticles;

- the control of atmospheric pressure inside it;

- maintaining a controlled humidity level;

- the total absence of particulate pollution.

Clean room assembly advantages

The forced recirculation of filtered air in a sealed chamber allows the Clean Room assembly service to position itself as a spearhead in the range of highly efficient and quality services that Panni & Lazzarini is able to offer to a wide range of companies.

The most different product sectors can benefit from a system whose purity, safety and hygiene are also guaranteed by the staff themselves, suitably trained, who wear sterile clothes and protections and work in the name of safety and continuous control of every procedure.

Discover all the benefits of outsourcing your production

Our company can provide customised and flexible solutions for each product sector.

We process every single order and deliver on time, even the most urgent ones.

We ensure comprehensive and inexpensive service also for small and medium-sized industries with low production.

From feasibility studies through logistics and warehousing, we make the most of every production phase.

2017 © Panni e Lazzarini S.r.l. - All right reserved |

Cookie policy | powered by

Sartoriadigitale